Table of Contents

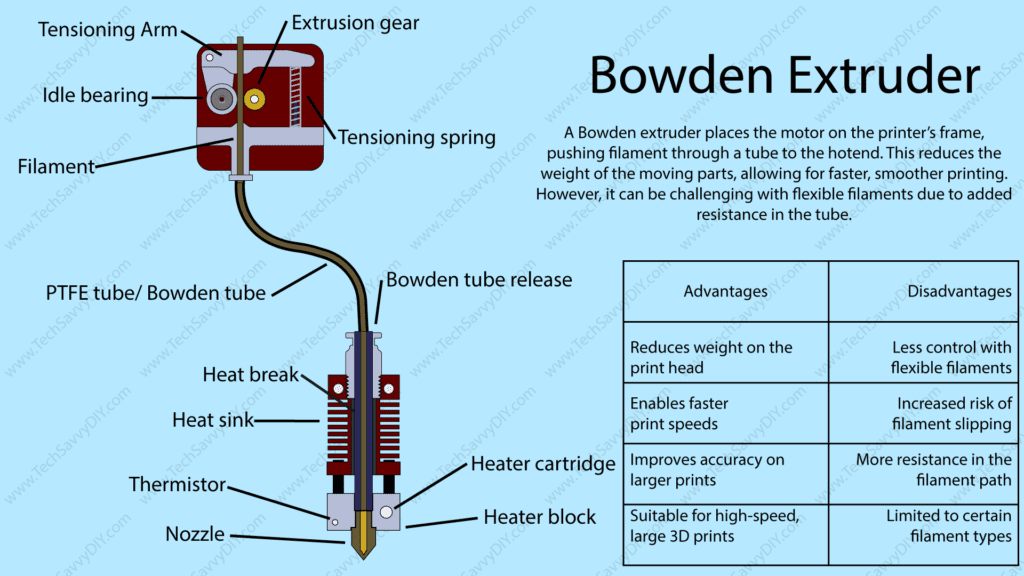

Bowden vs Direct Drive Extruders, a guide to choosing what suits you best. When getting into the world of 3D printing, one of the pivotal choices you’ll have to make is to choose between whether you want to go with a Direct Drive system or a Bowden extrusion system. They both have their unique advantages and challenges. It doesn’t mean that either of them is bad, it just means they’re each suitable for their different applications. In this article let’s try to find the most suitable extruder type for your needs.

What is an Extruder in 3D Printing?

Before we get into the specifics let’s first address what an extruder’s job is. The extruder is the mechanism that is used to feed the filament (ABS, PLA, etc.) to the hot end. During printing, the printer will not just use filament at a constant rate. The controller board will use the data in the G-Code to not only feed the filament into the hot-end but also to retract it (pull it back during non-print moves to avoid stringing).

Sometimes if your hot-end temperatures or extruder steps aren’t dialed in correctly, it will cause stringing and other kinds of artifacts in the print. Depending on which type of extruder you use, they will have different effects on the speed and quality of the print. We will discuss the pros and cons of each of these extruders further down the article.

Bowden extruders

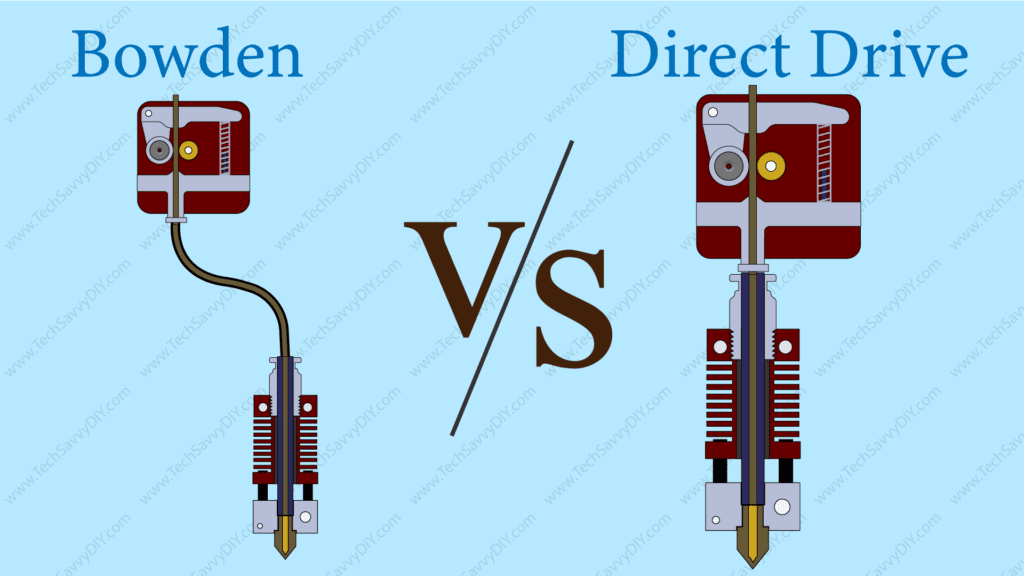

Let’s first talk about Bowden-type extruders. Few giveaway signs let you identify a Bowden extruder in a printer. If you see the filament going through a mechanical contraption mounted on the frame of the printer, rather than straight to the hot end, then you’re looking at a Bowden extruder.

You will also see the filament enter a tube after it exits the mechanical-looking contraption, carrying the filament from the extruder to the hot end. This tube is called the Bowden tube. It usually is made from a material called PTFE. Bowden extruder will use this tube to push the filament to the hot end. This design keeps the heavy filament-feeding parts away from the moving parts of the printer (the print head).

| Pros of Bowden Extruders | Cons of Bowden Extruders |

| Reduced Moving Mass | Retraction Settings |

| Improved Print Quality | Filament Flexibility Issues |

| Larger Build Volume | Complex Maintenance |

Pros

Reduced Moving Mass

Because the extruder is not mounted on the print head, the print head can move very fast compared to a direct-drive extruder. An extruder assembly is considerably heavy due to the stepper motor. So with the extruder mounted away, the print speeds and the wear on many components will be reduced (X-Axis belts and smooth rods wear, Z-Axis lead screw and lead screw nut wear).

Improved Print Quality

The lightweight print head will reduce the inertia of the print head and will provide better-quality parts. With the print head not weighing much it will be able to start the movement and come to a halt more easily which will help the stepper motors to not skip any steps while micro stepping provides smoother and more precise movements. This is very useful when you’re printing at very high speeds.

Larger Build Volume

This is not really a big thing but, since the extruder is not mounted on the print head, it will allow for the print head a little more room for movement. Which will result in a small increase in print volume.

Cons

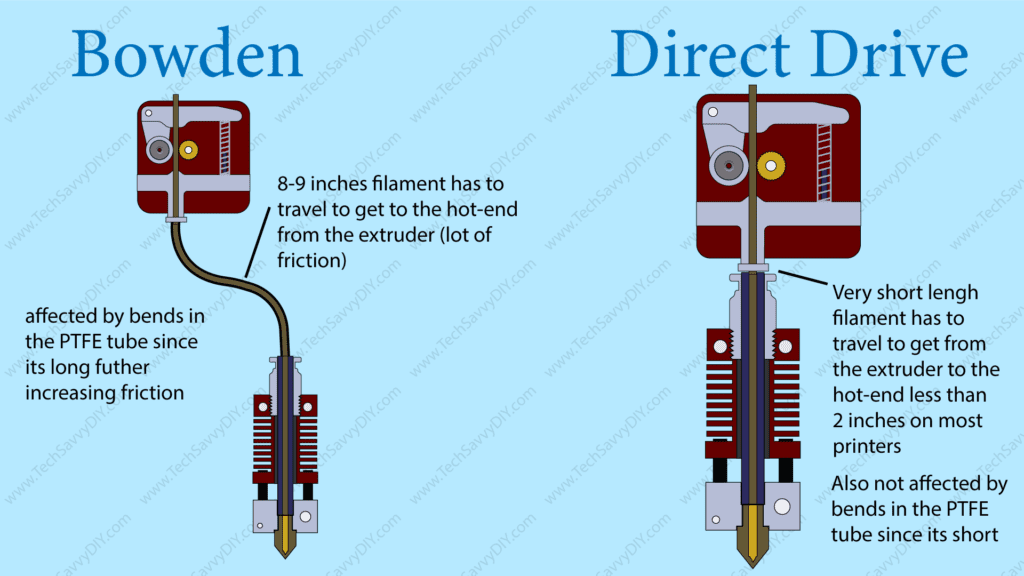

Filament Flexibility Issues

This is one of the biggest downsides of Bowden extruders. Since the filament has to travel through a long tube to reach the hot end, they struggle when pushing flexible filaments such as TPU and Soft PLA through the Bowden tube. It’s like trying to push a rope through a pipe. If you have done it, you will know is very difficult. Even with very little friction inside the PTFE tube, it’s difficult to push bendy filaments through.

In direct drive extruders, it is more like pulling the piece of rope through the end of a pipe (which is so much easier) instead of trying to push it in through the end.

Retraction Settings

Due to the reason, we talked about above it’s a bit difficult to dial in the retraction settings because there’s some distance between the extruder and the hot-end.

Other than it being harder to push certain filaments due to their bendy nature, the slack inside the Bowden tube makes the retraction movements sloppy. Dialing in the retraction settings is important because if not, then it will result in stringing and oozing. And we all know cleaning up strings is a pain in the ass.

Hard to troubleshoot print defects

By maintenance, I mean troubleshooting here. In a direct drive system, it’s much easier to find what is causing print artifacts such as layer shifting, and inconsistent extrusion width. But with Bowden-style ones it’s a tad more difficult.

Slower response time

The PTFE tube that links the extruder to the printhead has some natural flexibility, which can cause a bit of slack. If the tube bends too much or has excessive play, it can create friction, making it harder for the filament to move freely. This friction slows things down, causing a delay in the filament’s response to the extruder’s movements.

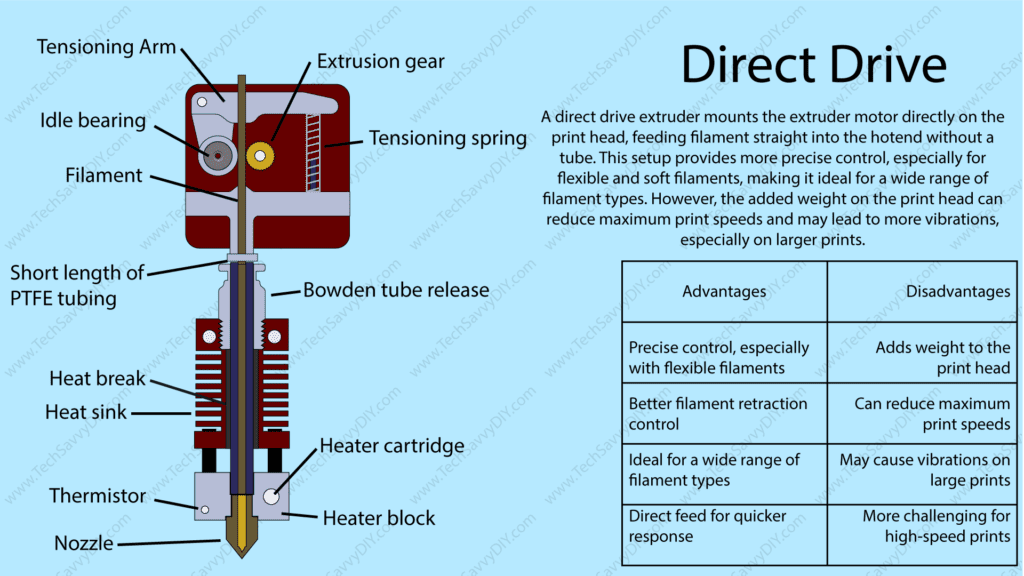

Direct Drive Extruders

In a direct drive extruder, the extruder is directly mounted on top of the hot end. With this, filament only needs to travel very little distance to reach the hot end.

| Pros of Direct Drive Extruders | Cons of Direct Drive Extruders |

| Better Handling of Flexible Filaments | Increased Moving Mass |

| Simpler Retraction Settings | Limited Print Speed |

| Ease of Maintenance | Smaller Build Volume |

Pros

Better Handling of Flexible Filaments

Because the filament only needs to travel a very short distance compared to a Bowden extruder, it handles flexible filaments like TPU very well (less friction due to the short length it has to travel to meet hotend). This reduces jamming and increases print quality aspects such as consistent layer height, and consistent extrusion width.

Simpler Retraction Settings

With direct drive extruders, it’s easier to dial in the retraction settings because the distance filament has to travel to get to the hot end is shorter. Because the extruder is so close to the hot end, there is no play or slack with the direct drive system. Which makes it easier to dial in the retraction settings.

Ease of Maintenance

Troubleshooting & maintenance of direct drive systems is easier when compared to a Bowden system.

Cons

Increased Moving Mass and Limited Print Speed

We can’t push a direct drive printer to the same speeds we can push a printer with a Bowden setup due to the weight on the print head. If we try to push it too far it will cause problems like Ghosting, ringing, and layer shifting in the prints. Due to the increased inertia of the print head, the stepper motor will likely skip steps.

Smaller Build Volume

If we consider a portable or a small printer a direct drive system won’t work well since the direct drive system will reduce the build volume by a considerable amount due to the extruder sitting on top of the print head and making that space unusable.

Conclusion

When choosing the right extruder for you, you should always think of what you are trying to achieve. Is it better print quality? faster print times? do you intend to print flexible filaments like TPU? You should pick one after reviewing what your end goal is. But have to admit, direct-drive extruders do offer many advantages over Bowden extruders.

Some people will say one is better than the other. But it would be best if you looked at the context or in what regard they say that it is better.

I hope you learned a few things from this article and I wish you good luck with choosing an extruder from the information you learned from this article.

FAQ

Is Bowden or Direct Drive better?

Direct drive is better when you need precision or plan to print with flexible filaments. Bowden Extruders are better for faster and larger prints. The main drawback of Direct Drive extruders is reduced speed due to added weight on the hotend.

Is direct drive better for 3D printing?

Yes, for smaller prints that require precision or if you want to print with flexible filament like TPU direct drive is the obvious choice. Only go with the Bowden extruder if you want faster and larger prints.

Does TPU need a direct drive?

Yes, trying to print flexible filaments like TPU with a Bowden extruder is like trying to push a wet noodle through a tube. To get proper extrusion a direct drive extruder is recommended.